Kategorien: Allgemein 3D Messarmtypen Gauge Rohrvermessung Scanner-Arm

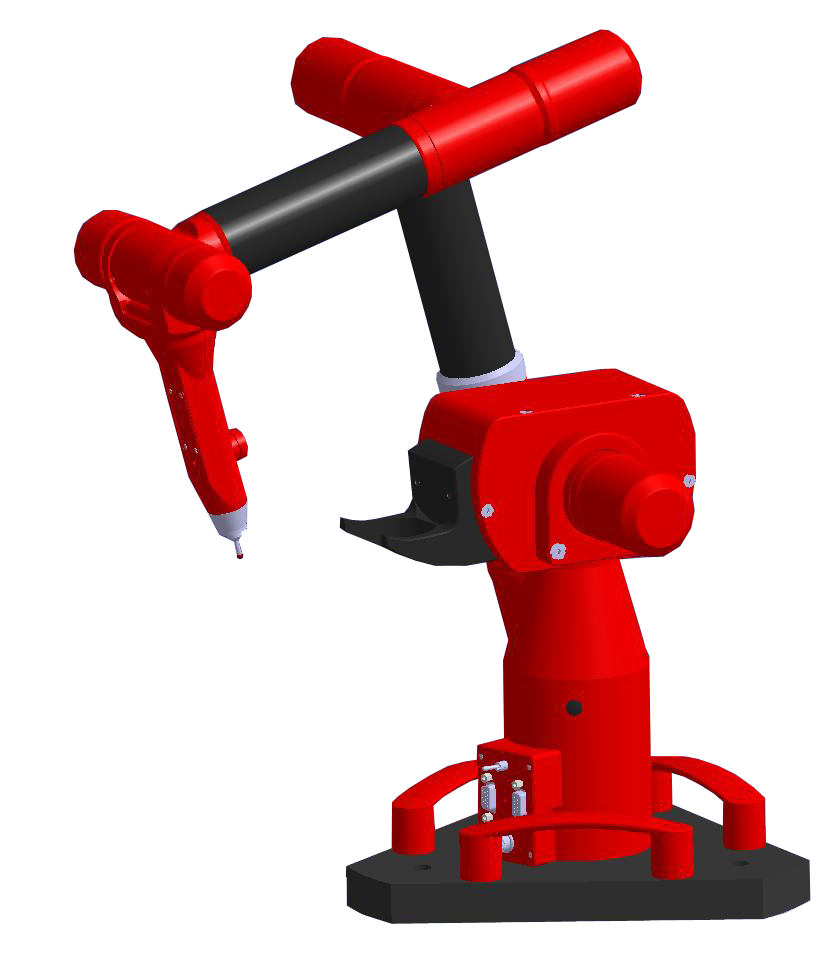

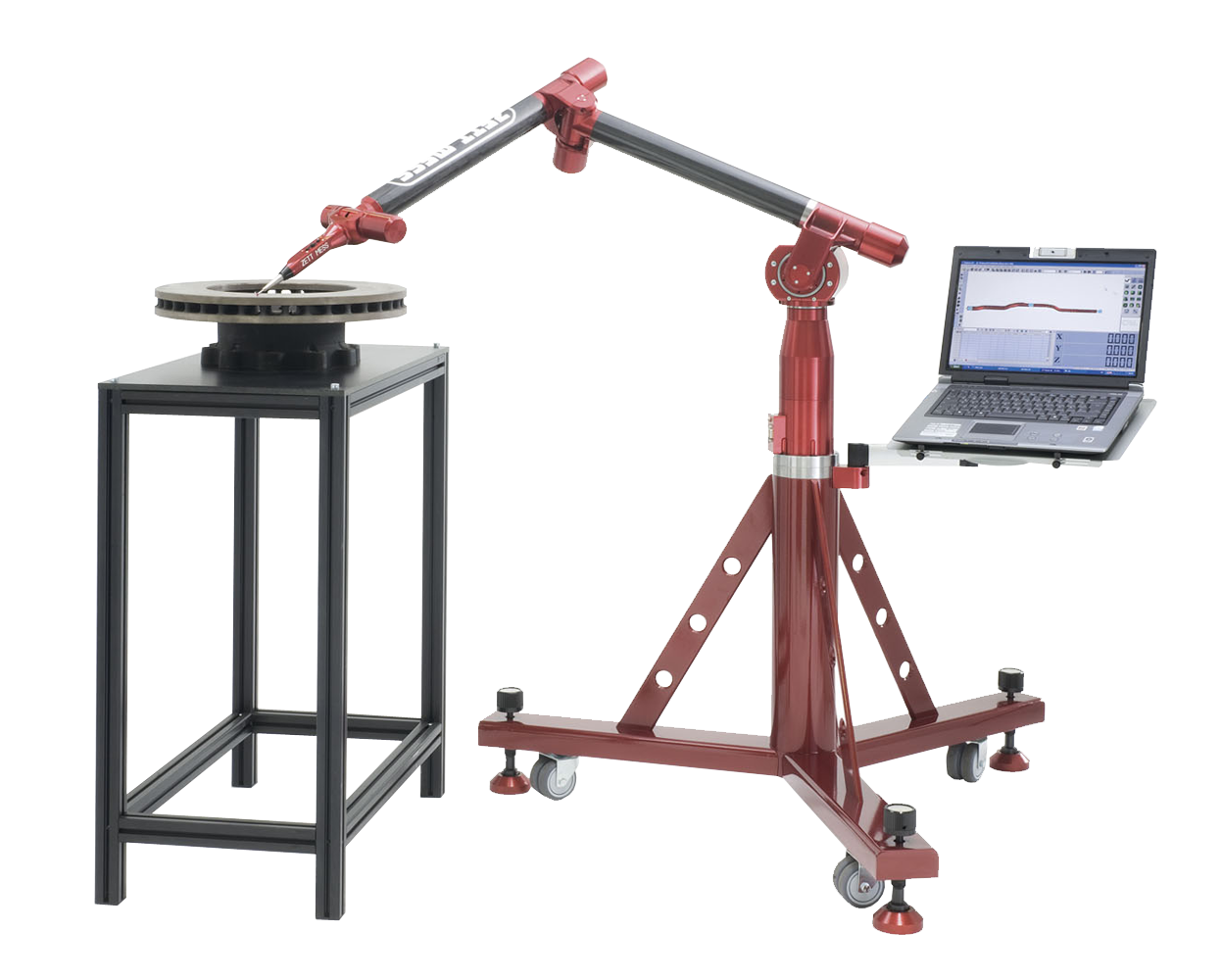

The mobile measuring arm AMPG – 3D measuring arm

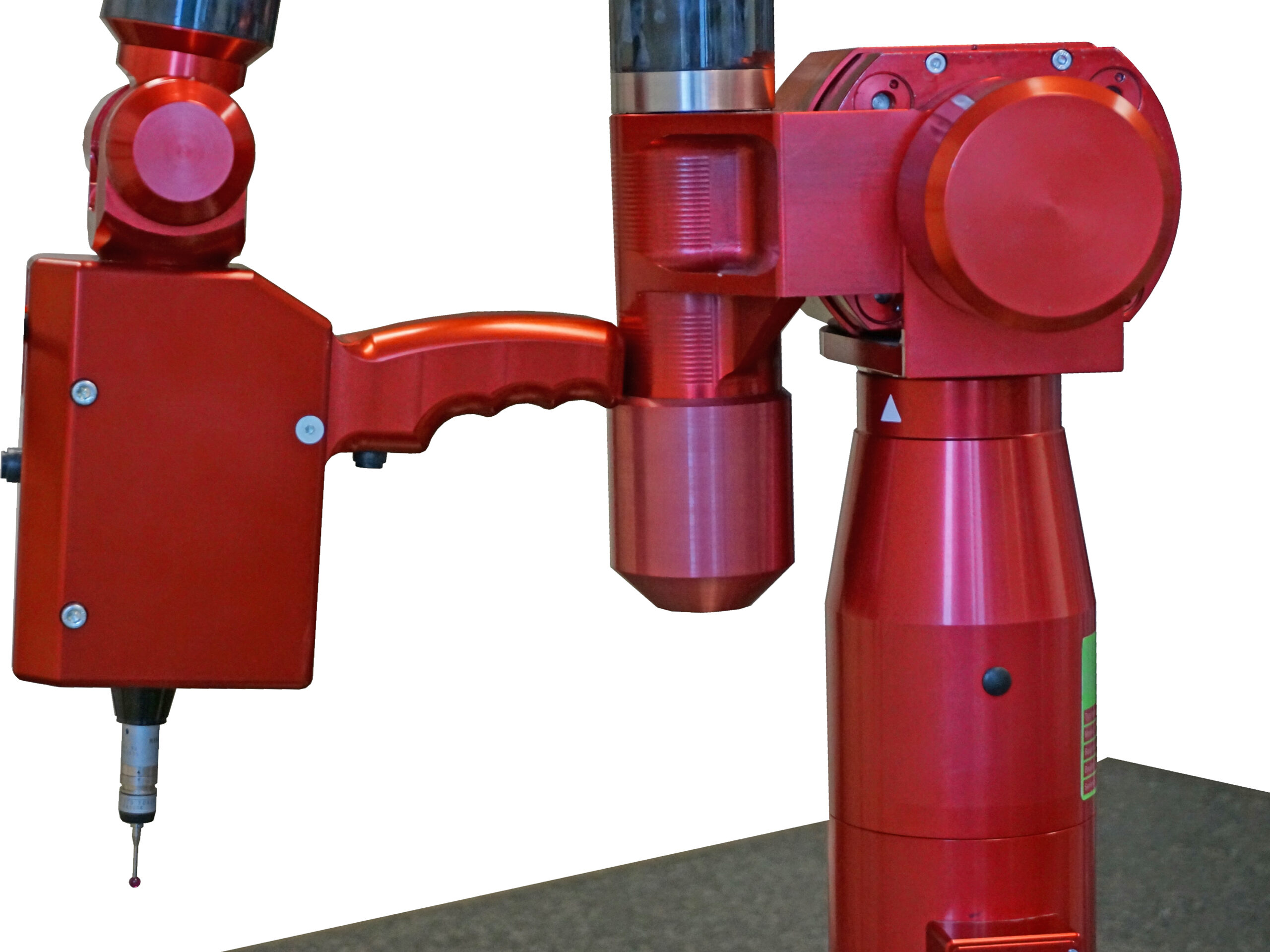

The mobile AMPG measuring arm from ZETT MESS is a transportable coordinate measuring machine. The use cases range from pure quality and production control in the production line to crash test measurements at measuring points that are difficult to access, interior measurements to scanning and digitizing surfaces in the design area. The 3D measuring arm AMPG can be optionally equipped with a fixed probe tip, a switching button, a laser sensor or a pipe measuring fork. The measured values are recorded either by pressing a button or automatically and transmitted to the connected computer.

To use

- Saving time and increasing productivity

- Cost reduction through portability

- Improved product quality

- Reduzierte Nacharbeit und stark verminderter Ausschuss

Merkmale AMPG

- Flexible mounting options: mounting base, tripod, magnetic base, 7th axis

-

Pneumatic parking brake

-

Electric stroke adjustment of the rollers

-

Remote control of the computer via an integrated mouse in the front joint area

-

Quick position changes thanks to electrical stroke adjustment of the rollers

Flexibility

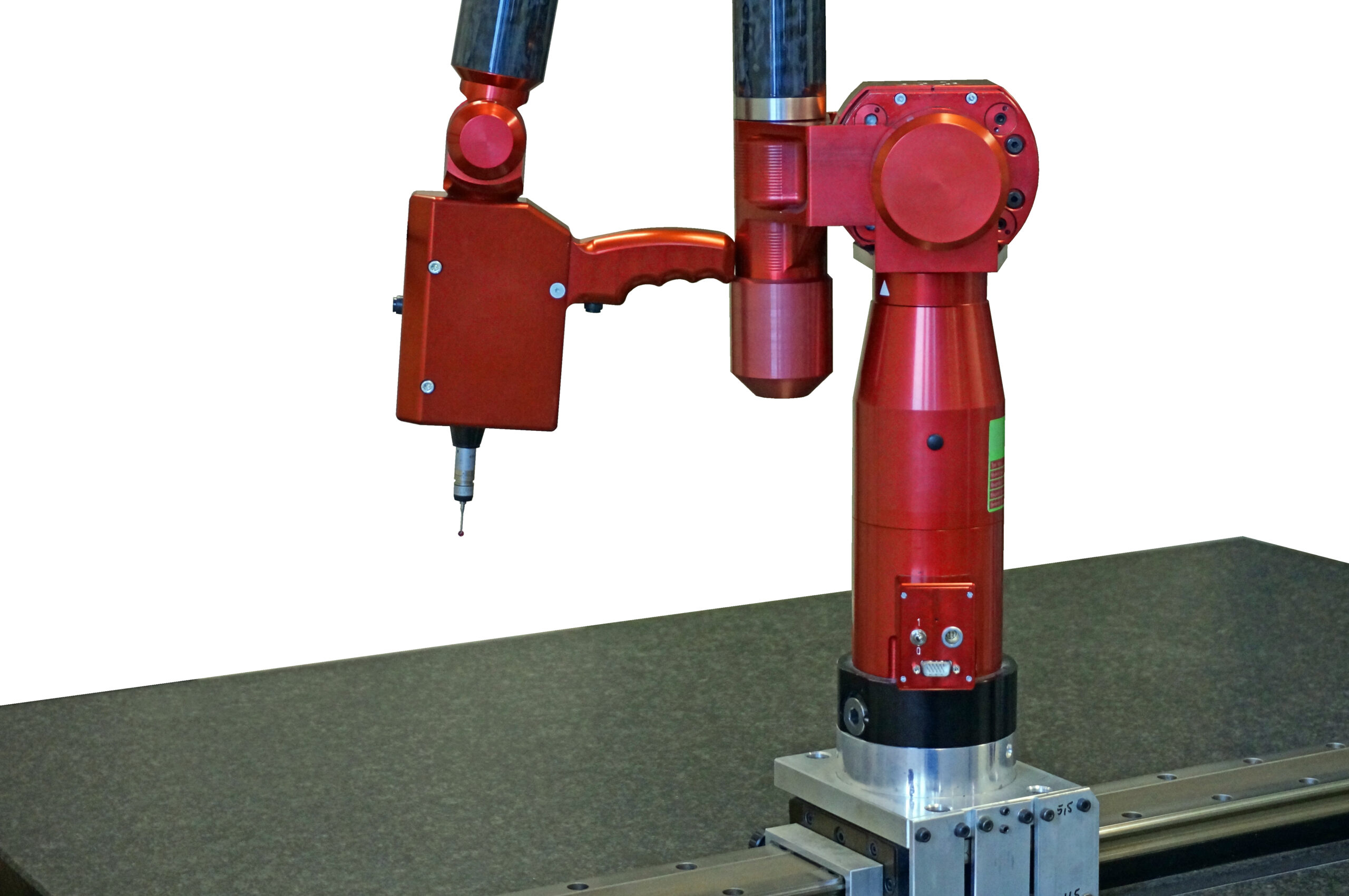

To expand the measuring range, ZETT MESS offers a 7th axis for the AMPG with precision linear guides depending on the design type as well as a measuring system, accuracy according to VDI/VDE 2617 per meter approx. 10 – 20 µm. The position of the 7th axis is automatically included in the 3D coordinates of the measuring tip by the measuring software, so that the operator can fully concentrate on his measuring task.

The AMPG Knick was developed for measuring tasks that require a high degree of flexibility. The AMPG Knick is ideal for particularly flat measurements in the interior of housings, cabins and vehicles as well as overhead measurements

3D measuring arm types

Manually guided, transportable 6-axis measuring arm (3D measuring arm) type Gauge

-

Short setup and set-up times

-

Can be used under workshop conditions

-

Immediate display and logging of results

-

Immediate display and logging of results

-

Recording for rigid and self-triggering buttons

-

One-handed operation and comfortable handling thanks to integrated weight compensation (strain relief)

-

Flexible mounting options

-

Adjustments possible upon customer request

Pipe measuring station with the Zett Mess 3D measuring arm

In conjunction with a laser pipe measuring fork from ZETT MESS and the FUTUREX TUBE software, the AMPG allows pipes to be measured quickly. To do this, the pipe measuring fork is simply guided over the pipe at the measuring points.

This interrupts two diagonally running laser beams and creates a total of four switching points that are used to determine the position. With the pipe measuring system, all pipes – delicate hydraulic pipes, exhaust pipes and large pipes – can be measured with just one system.

ZETT MESS offers the tube measuring forks in four sizes. The user-friendly tube measuring software Tube enables the quick measurement of bending angles, rotation angles, lengths and diameters, but also tube distortion data during the bending process. Correction data is passed directly to the CNC bending machine.

The 3D measuring arm AMPG can be quickly mounted from the pipe measuring station onto a tripod and can be used flexibly as a transportable measuring system elsewhere in the company.